Exploring the Versatility of Soda Ash in Modern Industries

Introduction

Soda Ash, also known as sodium carbonate (Na2CO3), is a crucial chemical used in various industries. Its diverse applications make it essential in food production, textile manufacturing, pharmaceuticals, and environmental management. In this article, we will explore the multifaceted roles of Soda Ash and its significance in modern industries, as well as best practices for selecting the right type for specific needs.

The Multifaceted Roles of Soda Ash

Food Processing

Soda Ash is important in the food industry, particularly as an acidity regulator and leavening agent. It’s used in baked goods to control pH levels, thereby enhancing texture and flavor. Additionally, Soda Ash contributes to the development of caramel color in certain confections. It’s critical to use food-grade Soda Ash that complies with safety standards for food processing.

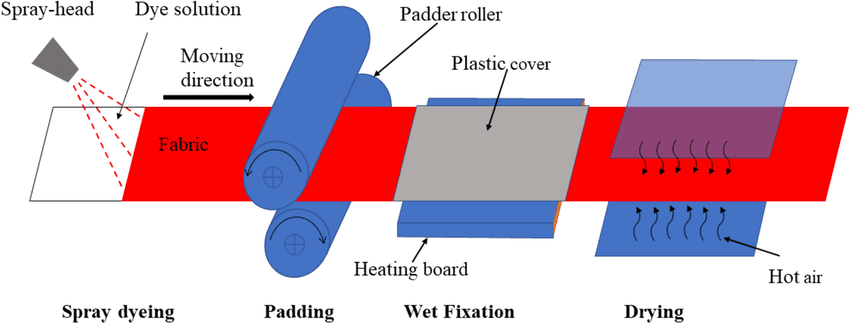

Textile and Dyeing Industry

In textile manufacturing, Soda Ash plays a key role in the dyeing process by fixing dyes on cotton fibers, ensuring vibrant and durable colors through multiple washes. It helps regulate pH within the dye bath, crucial for maintaining fabric quality. When choosing Soda Ash for textiles, prioritize a grade with high solubility and consistency for best results.

Pharmaceuticals

Soda Ash is vital in the pharmaceutical industry, used as a buffering agent in tablet formulations and other medicinal preparations. It ensures the stability and effectiveness of active ingredients, making it crucial in drug manufacturing. Pharmaceutical-grade Soda Ash must meet stringent purity standards to avoid introducing impurities into the final product.

Pulp and Paper Industry

The pulp and paper industry relies on Soda Ash during the chemical pulping process, breaking down lignin and facilitating pulp production for paper manufacturing. Soda Ash also enhances the bleaching process for high-quality, bright white paper. For paper production, Soda Ash with consistent chemical properties is essential to maintain paper integrity and brightness.

Soda Ash is increasingly significant in environmental management, particularly in air pollution control and wastewater treatment. It effectively neutralizes acidic emissions from industrial processes, reducing environmental impact. Additionally, it helps adjust pH levels in wastewater treatment, ensuring compliance with environmental regulations before discharge. When using Soda Ash for environmental purposes, consider its reactivity and compatibility with the specific treatment process.

Selecting the Right Soda Ash for Your Industry

Grade and Purity

The grade and purity of Soda Ash are critical for its suitability in various industrial applications. While industrial-grade Soda Ash is often sufficient for many uses, specialized applications such as pharmaceuticals or food production require higher purity levels. Always verify the chemical composition and ensure that the product meets industry-specific standards.

Packaging and Storage

Proper packaging and storage are vital for preserving the quality of Soda Ash. It should be kept in a dry, cool environment, as Soda Ash is hygroscopic and can absorb moisture from the air, potentially leading to clumping or product degradation. Packaging Soda Ash in moisture-resistant materials is recommended to maintain its quality over time.

Supplier Reliability

Selecting a reliable supplier is crucial for ensuring consistent quality and availability of Soda Ash. A reputable supplier provides not only high-quality products but also technical support and guidance on proper usage and handling. Look for suppliers with a strong track record in your specific industry and who adhere to strict quality control measures.

Innovations in Soda Ash Production

The production of Soda Ash has seen significant advancements, particularly in efforts to increase efficiency and reduce environmental impact. The Solvay process, which dominates Soda Ash production, has been refined to minimize waste and energy consumption. Emerging technologies are exploring the use of alternative raw materials and processes, further enhancing the sustainability and cost-effectiveness of Soda Ash production.

Conclusion

Soda Ash is a versatile chemical integral to various industrial applications, from food processing to environmental management. Its adaptability and efficacy make it a critical component in modern industrial processes. By understanding your industry’s specific requirements and selecting the appropriate grade and supplier, you can ensure that Soda Ash contributes to the success and sustainability of your operations.

For more detailed insights into the applications of Soda Ash or to discuss your specific needs, contact our team of experts or visit our website to explore our range of high-quality products.